COMPANY PROFILE

When the surface tread of a tyre is worn out, the tyre will not give proper road-grip and controlling. However, by applying a new tyre treads onto the old tyre casing, the tyre can be used for second time or repeatedly until the condition is no longer suitable for further retreading.

When the surface tread of a tyre is worn out, the tyre will not give proper road-grip and controlling. However, by applying a new tyre treads onto the old tyre casing, the tyre can be used for second time or repeatedly until the condition is no longer suitable for further retreading.

The operation cost has been one of the major concerns of today's large and small business entities. By retreading the old or worn tyres, this indeed helps reduce cost of tyre replacement. Retreading plays an important role in industries such as freight forwarding, transportation, tour & travelling, construction, container, & haulage services.

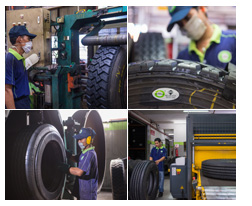

Olympic Retreads is working relentlessly to improve its manufacturing process to produce high quality retread tyres and meet customer expectation. By constantly upgrading its machinery and training the production staffs, not only Olympic Retreads is able to keep its pace ahead of the competitors but also reaps more markets share.

WHAT IS TYRE RETREADING

Retreading by definition is the removing of old tread and replacing it with a new tread to provide another tyre life, in essence it is Tyre Recycling. Basically they are two main types of Retreading system that is applied by most of the retreaders in the world, they are Hotcure and Precured Tyre Retreading.

Conventional or Hot Retreading

Hot retreading is the term used to describe the retreading process in which the curing of retread is done at a temperature of above 130°c. It employs a steel or aluminium mold with a tread design cast or machined into it.

This system is similar to the technology of new tyre manufacturing.

Uncured runner is applied to tyres in which the design will be molded into place during cure. Uncured rubber can be applied by strip winding extruders or slab extruders which provide the correct width and thickness to fill the tread design in a mold.

Rubber can also be purchased in a specified shape to apply around a tyre for mould cure. This is called die size or camelback rubber.

Cold or Precured Retreading

Cold or Precured Retreading

The term cold retreading was developed long ago to differentiate the system from that of hot retreading.

Cold retreading was then a term used to describe a process in which the final curing of retread is done at temperature lower than 130°c.

Precured retreading method is a system in which the tread is prevulcanized in a mould (matrix) either in a long slab form or a ring form before it is built onto the casing.

The Precured Tread system is a process by which a tread pattern is fully cured or vulcanized into the tread by using a press. The tread is then vulcanized onto a tyre casing using a bonding layer of uncured natural rubber.

Precured rubber has the tread design cured into the finished shape before the rubber is shipped to the retreader.

A thin layer of uncured natural rubber is sandwiched between the buffed surface of the Precured tread and the buffed surface of the tyre.

The tyre is vulcanized with heat, time and pressure in a curing chamber that bonds the tread to the casing. This thin layer is called Precured cushion or bonding gum.